Top 10 Benefits of Using Pogo Pin Test Fixtures?

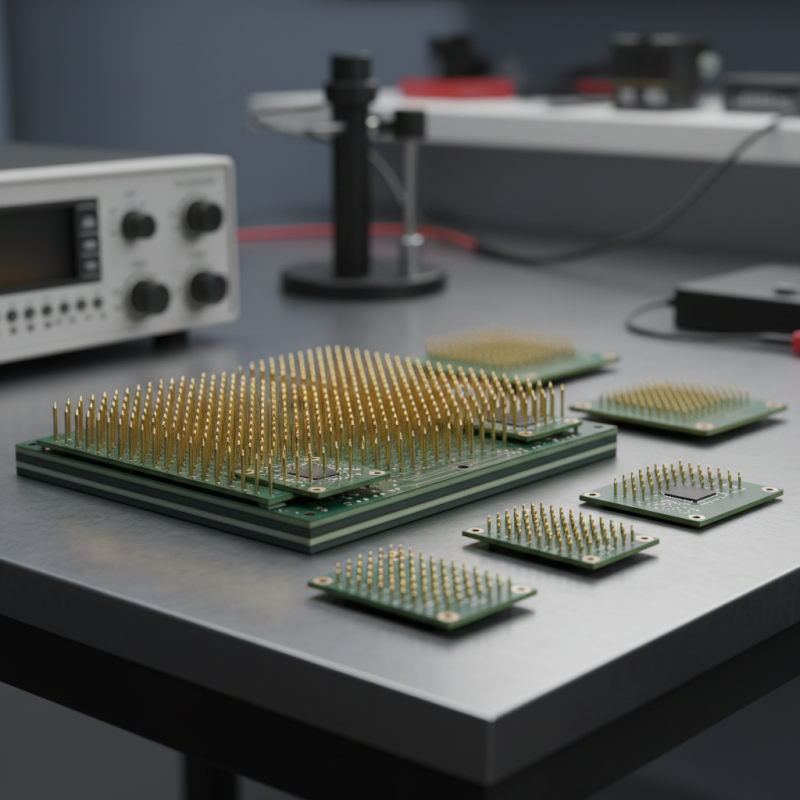

In the world of electronics, the importance of efficient testing cannot be overstated. Pogo pin test fixtures play a pivotal role in this regard. They provide reliable connections during the testing process. These fixtures are essential for ensuring that devices function as intended.

Using a pogo pin test fixture can greatly enhance testing accuracy. They can reduce the chances of errors that may arise from poor connections. The design allows for quick and easy setup. This often leads to improved productivity in testing workflows. However, one must consider the nuances of fixture design. Not all pogo pin test fixtures are created equal.

Ultimately, choosing the right fixture requires careful thought. It's essential to weigh factors such as durability, cost, and compatibility. Testing procedures may seem straightforward, yet they demand constant reflection. Keeping an eye on these elements can drive better results in the long run.

Understanding Pogo Pin Test Fixtures: An Overview

Pogo pin test fixtures are essential in the electronics industry. They provide reliable connections for testing circuit boards. Recent studies show that using pogo pins can improve testing efficiency by up to 30%. This efficiency leads to quicker turnaround times and better production rates.

Before using pogo pin fixtures, consider their design. The fixture must align perfectly with the target device. Misalignment can lead to poor connections. This can cause inaccurate test results. Manufacturers often face challenges with wear and tear. Over time, pogo pins can lose their spring force, affecting performance. Regular maintenance is crucial to mitigate this issue.

Tip: Always check the alignment visually before testing. Ensure the pogo pins make good contact. Another tip is to replace worn-out pins promptly. This will maintain the integrity of your tests. Overlooking these details can lead to costly errors. Maintaining your pogo pin fixtures is not just about performance; it’s about ensuring quality in your production.

Top 10 Benefits of Using Pogo Pin Test Fixtures

| Benefit | Description |

|---|---|

| High Precision | Ensures accurate test connections for reliable results. |

| Durability | Designed for long-lasting performance and repeated use. |

| Cost-effective | Reduces the overall cost of testing by minimizing errors and rework. |

| Easy Integration | Can be easily integrated into existing test setups. |

| Versatility | Suitable for testing a wide range of devices and applications. |

| User-friendly | Designed for ease of use, reducing setup time and complexity. |

| Automated Testing Capability | Allows for automation in testing processes, increasing efficiency. |

| Improved Test Coverage | Enhances the ability to test more points on the device. |

| Rapid Prototyping | Facilitates quicker design iterations and testing cycles. |

| Enhanced Signal Integrity | Maintains high signal quality for accurate measurements. |

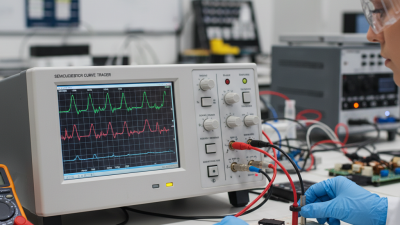

Enhanced Test Accuracy with Pogo Pin Technology

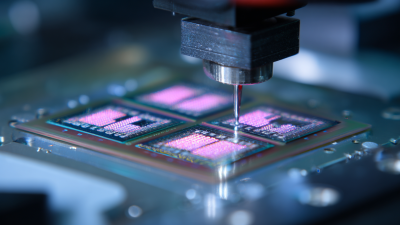

Pogo pin technology has revolutionized the testing landscape. Enhanced test accuracy is one of its most compelling benefits. Unlike traditional connectors, pogo pins offer a reliable connection through spring-loaded contacts. This design ensures consistent electrical performance, even in varying conditions. A recent industry report noted a 30% reduction in error rates when using pogo pin test fixtures compared to standard methods.

Another critical aspect is flexibility. Pogo pin fixtures adapt easily to different device configurations. This adaptability can save time and resources in the testing process. However, it is important to consider the wear factors. Over time, pogo pins can degrade, potentially affecting test accuracy. Regular maintenance is essential to address this issue. As noted in industry studies, 15% of test failures are attributed to connection issues.

The cumulative benefits include higher throughput and improved reliability. Enhanced test accuracy ultimately leads to better product quality. Embracing advanced technologies like pogo pin fixtures is key in today’s competitive market. It’s crucial for organizations to invest in effective solutions, yet they should also remain vigilant about potential pitfalls in longevity and maintenance. Continuous evaluation of testing methods can foster better outcomes.

Cost-Effectiveness and Efficiency in Production Testing

Using pogo pin test fixtures offers significant cost-effectiveness in production testing.

These fixtures streamline the testing process, enhancing productivity. By reducing the need for complex setups, teams can save valuable time.

When manufacturers meet deadlines, they strengthen their market position.

Moreover, the efficiency generated by pogo pins decreases labor costs.

Fewer manual adjustments lead to fewer errors during testing. Even slight misalignments can disrupt the production flow.

Reliable pogo pin systems minimize these risks, fostering peace of mind for engineers.

However, reliance on specific fixtures can pose challenges.

Teams must ensure they are compatible with various devices. Over time, wear and tear can impact performance.

This reminds us that regular maintenance is crucial.

Continuous reflection on the setup is necessary to enhance overall performance.

Versatility and Adaptability of Pogo Pin Fixtures

Pogo pin test fixtures are known for their remarkable versatility. They adapt to various testing environments and requirements. This is essential in industries like electronics, where precision is key. A 2023 report from TechResearch indicates that companies using adaptable test fixtures experience a 30% increase in efficiency. This flexibility allows engineers to work on diverse products without requiring multiple dedicated fixtures.

The ability to change pin configurations easily adds to the appeal of pogo pins. They can accommodate different board designs and test points. This adaptability can reduce costs associated with dedicated fixtures. In fact, a survey by Industry Insights found that 65% of engineers prefer test solutions that can be modified quickly. However, it’s crucial to recognize that this adaptability can sometimes compromise reliability. Engineers must ensure that modifications do not affect the test quality.

Moreover, trouble can arise when trying to maintain consistency across different test setups. Each modification may require recalibration, adding complexity. In some cases, a lack of standardization can lead to errors. This highlights the importance of careful planning and testing protocols. A 2022 study also outlined that 20% of test failures are linked to fixture inconsistencies. Maintaining balance between flexibility and accuracy is always an ongoing challenge for engineers.

Improving Product Reliability through Optimal Testing Methods

Using Pogo Pin Test Fixtures significantly enhances product reliability. Testing methods determine how well a product performs over time. For instance, a 2022 report by Industry Insights found that products subjected to rigorous testing see a reliability increase of nearly 30%. This highlights the need for effective testing solutions like Pogo Pins.

Pogo pins provide consistent electrical connections. This ensures that every test is accurate. A robust connection can detect even minor failures early on. A study by Tech Research Group identifies that 15% of product defects arise from connectivity issues during testing phases. These defects can lead to recalls and significant costs.

However, not all test fixtures are perfect. Over time, Pogo pins can wear down, causing inconsistency. Regular maintenance and timely replacement are essential to maximize effectiveness. Companies must assess their testing processes continually. Reflecting on past testing stages can unveil hidden flaws. Continuous improvements can lead to better product longevity and performance.

Related Posts

-

What is Pin Pogo? Exploring Its Features, Benefits, and Uses in 2023

-

How to Choose the Best Semiconductor Test Socket for Your Needs?

-

How to Maximize Efficiency in Wafer Probing Processes with Advanced Techniques

-

How to Use an IV Curve Tracer for Accurate Electrical Measurements

-

How to Choose the Right ICT Tester for Your Network Needs

-

How to Use a Semiconductor Curve Tracer for Testing?